Present

NowPresent ~ 2021

2025

-

06

National R&D Project - Development of highly uniform, high speed vdW material synthesis technology and equipment in semiconductor grade

-

01

Obtained a certificate of core strategic technology for materials, components, and equipment [ Semiconductor heat treatment equipment manufacturing technology ] (Ministry of Trade Industry and Resources)

2024

-

04

National R&D Project - Development of core technology for large-area low-temperature hybrid bonding

2022

-

09

Developed semiconductor equipment_LAB

-

04

National R&D Project (semiconductor) - Developed next generation intelligent semiconductor technology

-

02

Developed semiconductor equipment_RT-CVD

2021

-

12

National R&D Project (global) - Developed oxide semiconductor manufacturing technology using laser annealing process

-

11

Developed vacuum auto laminator

-

10

Received the Presidential Citation on Display Day

-

07

Established a subsidiary, Viatron Systems, Inc

Growth Period

2020 ~ 2011

2020

-

04

National R&D Project (solution type) - Establishment of display innovation process platform for electronic parts industry technology development

2018

-

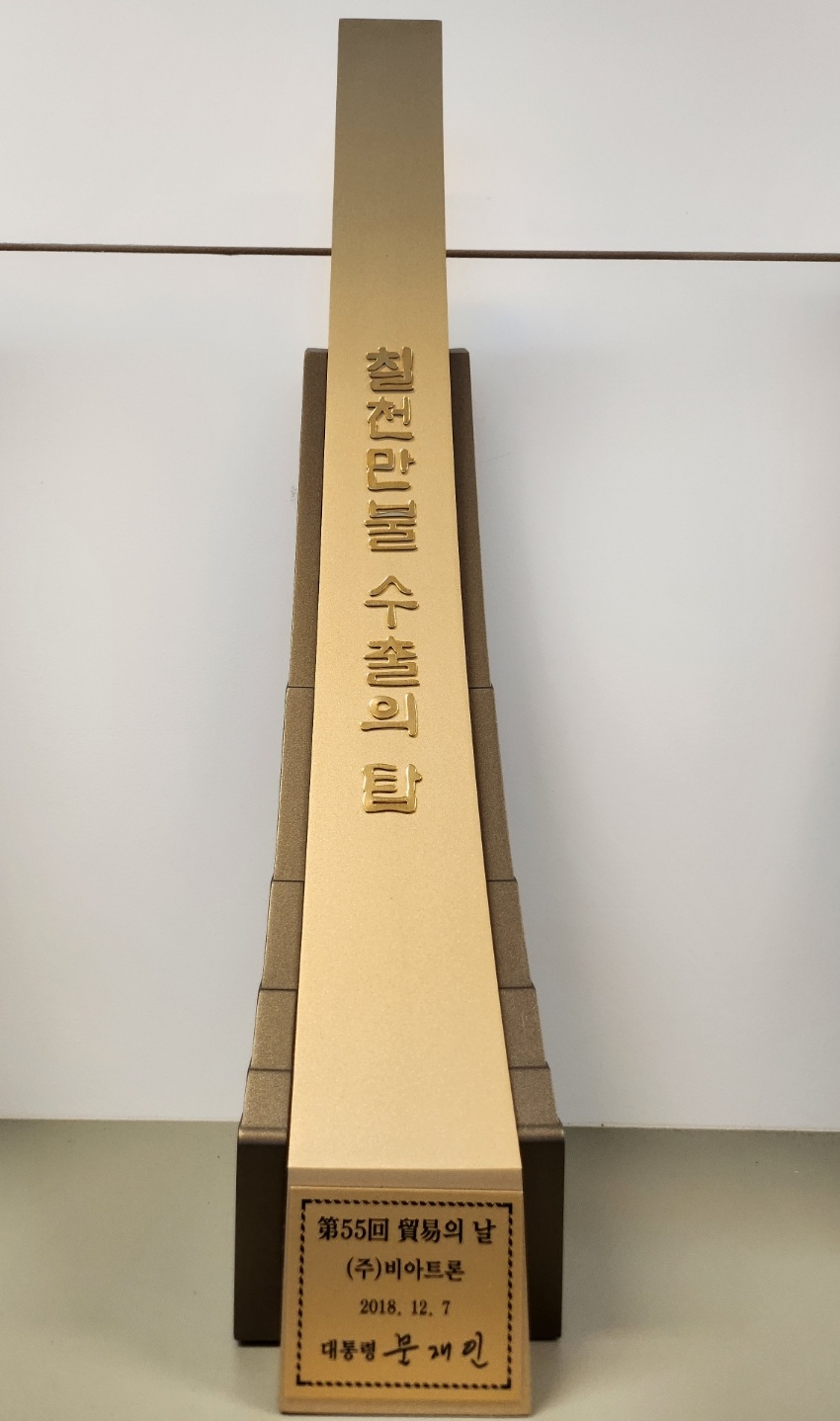

12

Won the $70M Export Tower (Korea International Trade Association)

-

11

Venture 100 Billion Company (Ministry of SMEs and Startups)

-

10

Excellent Youth Employer in Suwon (Suwon regional quadripartite councils of labor, management, civic groups and government)

2016

-

12

Won the $50M Export Tower (Korea International Trade Association)

-

11

Established a subsidiary, InterValue Partners Co., Ltd.

-

10

Won the Excellence Award at the Korea IR Awards in 2016

-

10

Selected as an Excellent Employer for Women in Gyeonggi-do in 2016

-

03

The year of the first entry of 6G PIC equipment into China (BOE)

2015

-

09

Developed and supplied LTPS inline equipment system for oxygen control

-

07

Signed an agreement with Future Africa Foundation to support education projects in Malawi

-

05

Developed oxide semiconductor thin film coating and heat treatment R2R system for flexible display

-

01

Developed TFT backplane coating equipment for flexible display

2014

-

12

Awarded by the Gyeonggi Venture Business Association and the Ministry of Trade, Industry and Energy in 2014

-

11

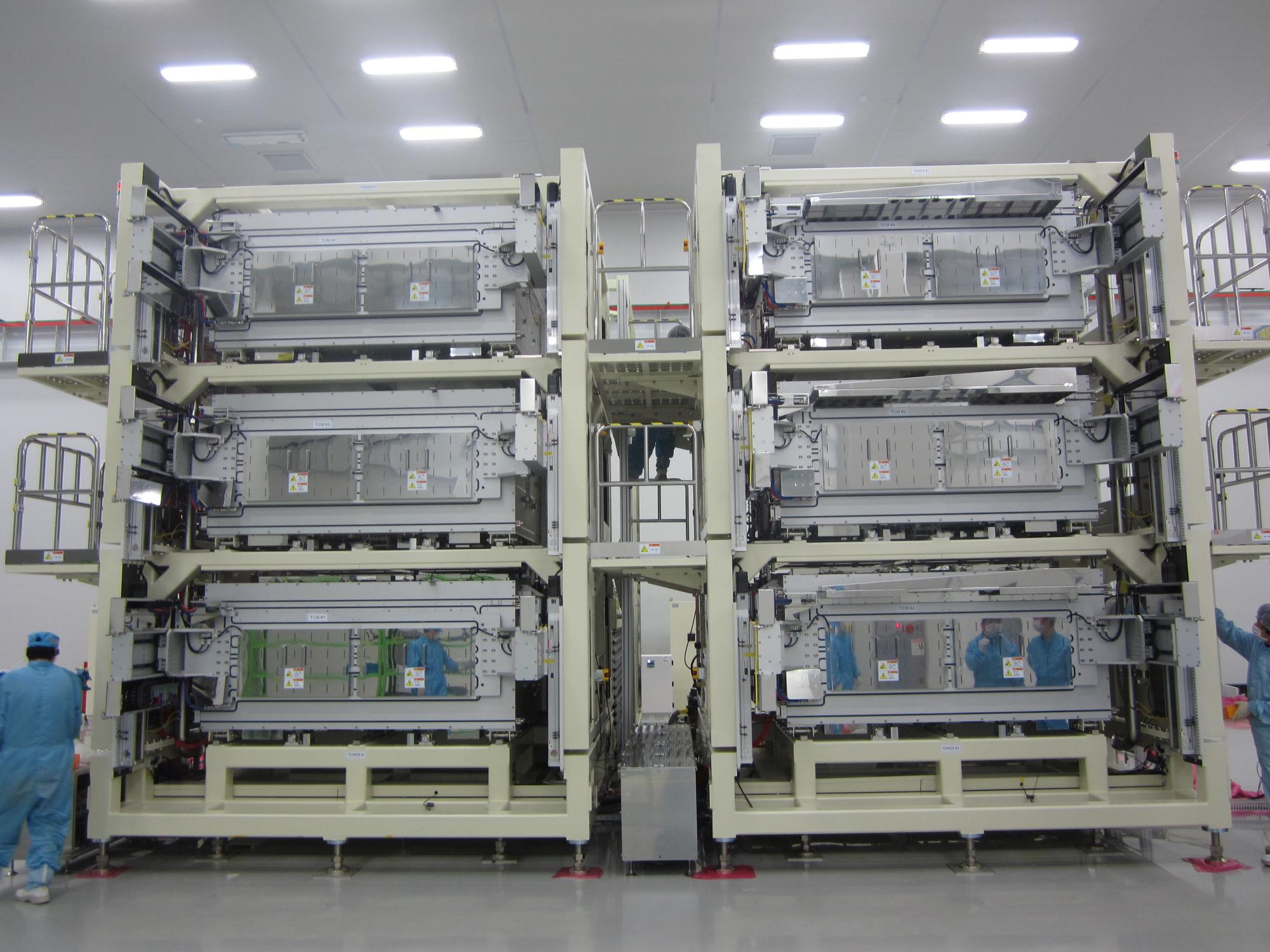

Developed and supplied Max CAPA Batch-Type high temperature heat treatment system

-

03

Gyeonggi Governor's Citation for Model Taxpayers (Local Tax)

-

03

Citation for "Model Taxpayers" on the 48th Taxpayers' Day (National Tax)

2013

-

11

Gyeonggi Governor's Citation for Venture Industry Development

-

11

Won the $20M Export Tower (Korea International Trade Association)

-

06

Won the Best Next Generation Enterprise Award at the 6th Korea KOSDAQ Awards

-

06

Relocated to new headquarters and factory (Suwon Industrial Complex 3, Gosaek-dong, Suwon-si)

-

05

Selected as the "2013 KOSDAQ Market Hidden Champion"

-

05

Selected as the "2013 World Class 300 Project Grand Prize"

2012

-

11

Groundbreaking ceremony for new factory (Suwon Industrial Complex 3)

-

10

Selected as one of the KB Hidden Star 500

-

05

Listed on KOSDAQ Exchange

-

02

Developed the 8th generation high functional glass substrate manufacturing process (pre-compaction)

2011

-

10

Received a citation from the Minister of Knowledge Economy at the Venture Business Awards (CEO Kim Hyoung-June)

-

09

Supplied SGS crystallization inline equipment system for 8th generation AMOLED

-

06

First entry of the LTPS heat treatment mass production equipment for AMOLED into the Chinese market (CENTURY)

-

04

Developed and supplied heat treatment equipment for flexible E-paper/AMOLED

-

01

Achieved $16.7M in overseas sales

Establishment Period

2010 ~ 2001

2010

-

11

Selected for SMD CREPAS task (advanced development of high temperature productivity innovation RTA for 8th generation SGS crystallization for large screen OLED TVs)

-

11

Small and Medium Business Administration's task with conditional purchase option

-

10

Signed a contract for a new factory site in Suwon Industrial Complex 3 (7,370㎡)

-

07

First entry of the LTPS heat treatment mass production equipment for AMOLED into the Taiwanese market (AUO)

-

05

Relocated to expanded headquarters and factory (Suwon Industrial Complex 1, Gosaek-dong, Suwon-si)

-

04

Developed and delivered the world's first 8th generation oxide TFT heat treatment equipment (WVA)

2009

-

08

Supplied LTPS crystallization heat treatment mass production equipment for AMOLED for the domestic market

-

06

Selected for national development project of thin-film solar cell APCVD for the renewable energy technology development project

2008

-

12

Mass production of the world's first non-laser crystallized AMOLED using Viatron’s equipment (FE-RTP V900)

-

11

Received an order for oxide TFT active film heat treatment system

-

07

Developed APCVD system for deposition of thin film solar cell transparent electrode

-

06

Developed heat treatment system for oxide TFT production

2007

-

05

Selected as an excellent venture company (Technology Guarantee Fund)

-

04

Received a citation from the Minister of Trade, Industry and Energy for display equipment

-

04

Selected as one of the Kibo A+ Members by the Technology Guarantee Fund

-

02

Supplied 4th generation LTPS rapid heat treatment equipment

-

01

Developed 4th generation normal pressure metal doping equipment (model name : AMD-900)

2006

-

12

Acquired S-Mark certification

-

06

Relocated to expanded headquarters (Micro Office Building, Gasan-dong, Seoul)

-

05

Acquired Technologically Innovative SMEs(INNO-BIZ) certification

2005

-

06

Participated in the 21st Century Frontier National Project

-

03

Supplied 2nd generation LTPS rapid heat treatment equipment

-

03

Developed large-area AMOLED using Viatron’s non-laser technology

-

03

Completed development of 4th generation LTPS rapid heat treatment equipment (model name : FE-RTP V900)

-

02

Developed LTPS LCD using Viatron’s non-laser technology

2004

-

10

Participated in large-area AMOLED next-generation growth engine project

-

02

Developed the world's first AMOLED product using non-laser technology

2003

-

07

2nd generation LTPS rapid heat treatment equipment (model name : FE-RTP V400)

2002

-

07

Established Viatron Technologies Inc. Corporate Research Center

-

02

Registered as a venture company

2001

-

12

Established Viatron Technologies Inc (Gasan-dong, Geumcheon-gu, Seoul), with an initial capital of KRW 50M